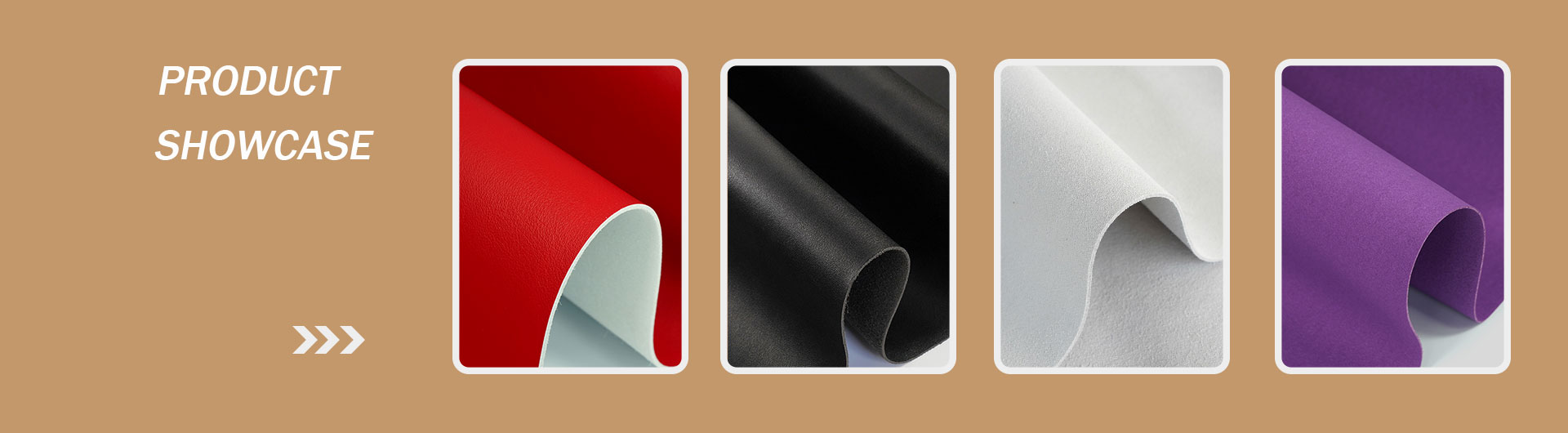

Nonwoven Shoe Lining Factory is a specialized manufacturing facility dedicated to producing high-quality, functional nonwoven shoe linings for footwear brands, shoe manufacturers, and suppliers worldwide—focused on delivering materials that balance comfort, durability, and cost-efficiency for diverse shoe types. Our core product range leverages advanced nonwoven fabric technologies, including spunbond, needle-punched, and hydroentangled nonwovens, each engineered to address key footwear needs: spunbond nonwovens offer exceptional strength and breathability (ideal for casual shoes and sneakers), needle-punched options provide enhanced thickness and cushioning (perfect for work boots or hiking shoes), and hydroentangled linings deliver a ultra-soft, skin-friendly texture (suitable for dress shoes or children’s footwear). All our linings feature moisture-wicking properties to draw sweat away from the foot, preventing odor buildup and discomfort during all-day wear, while anti-microbial treatments (available as a custom add-on) further enhance hygiene. We prioritize precision in production: our factory uses automated cutting and rolling equipment to ensure consistent material thickness (ranging from 0.2mm to 1.0mm) and width, while strict quality control processes include testing for Breathability (дишане), abrasion resistance (to withstand repeated foot movement), and colorfastness (to avoid dye transfer onto socks). We also offer flexible customization to meet brand-specific requirements: clients can select from a spectrum of colors, request functional upgrades (such as water-resistant coatings for outdoor shoes or flame-retardant layers for work footwear), and adjust material density to align with design goals. Committed to sustainability, we incorporate recycled polyester fibers into our nonwoven blends (reducing plastic waste) and use eco-friendly dyes with low VOC emissions. Our factory provides end-to-end support, from sample development (to validate fit and performance) to scalable bulk production, ensuring timely delivery to meet clients’ manufacturing schedules.

Телефон:+86-18965687670

Имейл:info@Shoe-Materials.com

Адрес: Адрес: 1-1-417 Xinjinghuating Luocheng Town Huian County Quanzhou City Quanzhou Province Fujian China

Авторско право 2011-2025 © www.shoe-materials.com Всички права запазени от WINIW Shoe Materials.