I always consider my job safety requirements and comfort when choosing working boots. Steel toe boots give maximum protection, especially in high-risk jobs like construction or heavy manufacturing. Soft toe boots feel lighter and suit long hours on my feet in lower-risk settings. OSHA requires protective footwear if foot injuries are possible, so my choice depends on the specific hazards I face.

- Steel toe boots are essential for workers in industries with risks from falling objects or punctures.

- Soft toe options work well in retail or light manufacturing where injuries are less likely.

Key Takeaways

- Steel toe boots provide maximum protection against heavy objects and are essential for high-risk jobs like construction and manufacturing.

- Soft toe boots are lighter and more comfortable, making them suitable for low-risk environments where safety hazards are minimal.

- Always check workplace safety requirements before choosing footwear; some jobs mandate steel toe boots for compliance.

- Consider comfort and fit when selecting boots; poorly fitting footwear can lead to blisters and fatigue.

- Evaluate the work environment for hazards like sharp objects or slippery surfaces to choose the right boot features.

- Durability matters; look for high-quality materials and construction methods to ensure your boots last longer.

- Composite toe boots offer a balance of protection and comfort, ideal for those needing safety without the weight of steel.

- Testing boots in-store helps ensure a proper fit, which is crucial for comfort and safety during long shifts.

Working Boots Comparison

Steel Toe vs. Soft Toe

When I choose between steel toe and soft toe working boots, I always start by comparing their main features. The right pair can make a huge difference in my daily comfort and safety. I created a table that breaks down the most important differences:

| Feature | Steel Toe Boots | Soft Toe Boots |

|---|---|---|

| Safety | Provides maximum protection against heavy objects. | Minimal protection; not suitable for heavy lifting. |

| Comfort | Heavier and less flexible, can cause discomfort. | More comfortable and flexible for daily wear. |

| Weight | Generally heavier due to steel components. | Lighter, making them easier to wear for long periods. |

| Cost | Often affordable and widely available. | Varies, but generally similar in price to steel toe. |

| Best Use Cases | Ideal for construction, warehouses, and farming. | Suitable for office work, light gardening, and casual wear. |

I rely on steel-toe boots when I need maximum protection. These boots shield my feet from falling objects and heavy equipment. I often see them required in construction, heavy manufacturing, and warehousing jobs. Soft toe boots, on the other hand, feel much lighter and more flexible. I prefer them when I work in low-risk environments or spend long hours standing or walking.

Key Differences

I notice that the biggest difference comes down to safety and comfort. Steel toe boots offer the highest level of protection, which is essential in hazardous workplaces. Soft toe boots focus on comfort and flexibility, making them ideal for jobs where safety risks are minimal.

Tip: I always check my workplace requirements before choosing safety footwear. Some employers mandate safety-toe boots for specific tasks.

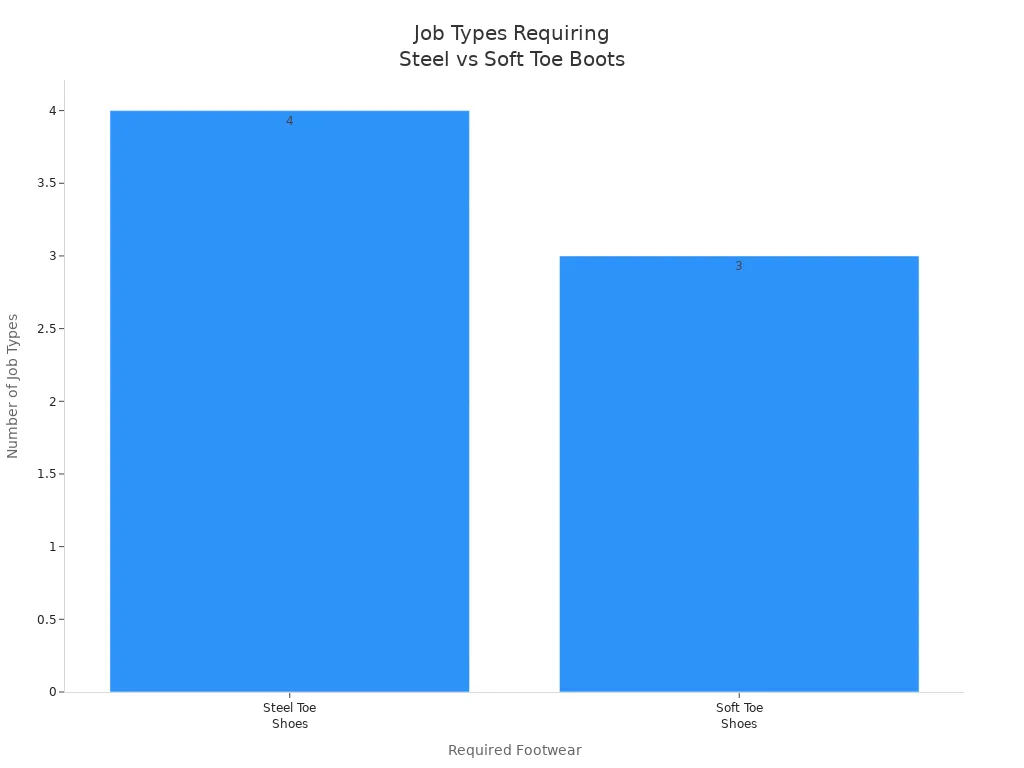

Here a quick look at which jobs typically require each type:

| Job Type | Required Footwear |

|---|---|

| Low-risk environments | Soft Toe Shoes |

| Construction | Steel Toe Shoes |

| Heavy manufacturing | Steel Toe Shoes |

| Mining | Steel Toe Shoes |

| Warehousing (overhead storage) | Steel Toe Shoes |

| Retail stockrooms | Soft Toe Shoes |

| Logistics | Soft Toe Shoes |

From my experience, I always choose steel toe boots for jobs with a high risk of foot injuries. I switch to soft toe boots when I need comfort for long shifts in low-risk settings. The right working boots depend on the hazards I face and the comfort I need throughout the day.

Steel-Toe Boots

When to Choose

High-Risk Jobs

I always reach for steel-toe boots when my job exposes me to serious hazards. In environments like construction sites, manufacturing plants, and mining operations, I face risks that demand the strongest toe protection available. Steel-toe boots shield my feet from falling objects, compression hazards, and sharp materials. These boots also help me navigate slippery floors and uneven terrain safely.

- Falling objects

- Compression hazards

- Electrical hazards

- Sharp materials

- Slippery floors

- Uneven terrain

I rely on steel-toe boots for jobs where heavy equipment moves overhead or where sharp debris covers the ground. The safety benefits of steel-toe boots make them the best choice for workers who need reliable foot protection every day.

Heavy Industry

In heavy industry, I see steel-toe boots as essential. When I work around forklifts, cranes, or large machinery, I need safety footwear that meets strict standards. Steel-toe boots use alloy caps to deliver the strongest toe protection against impact and compression. I trust these boots to keep my feet safe in the toughest conditions.

Pros

Maximum Protection

Steel-toe boots offer the highest level of protection for my feet. The alloy toe caps withstand heavy impacts and compression, meeting rigorous safety standards. I always check for ASTM F2412 and ASTM F2413 ratings before buying safety-toe boots. These standards guarantee that the boots provide reliable toe protection.

| Standard | Description |

|---|---|

| ASTM F2412 | Standard test methods for foot protection, including impact and compression. |

| ASTM F2413 | Performance requirements for safety toe cap footwear. |

- Safety-toe boots are rated for impact protection at either 50 or 75 foot pounds.

- Compression ratings reach 1,750 or 2,500 pounds, depending on the boot.

- These ratings assure me that steel-toe boots can handle heavy objects falling or rolling onto my feet.

Durability

I choose steel-toe boots for their durability. The alloy toe caps resist dents and cracks, even after months of hard use. The tough leather and reinforced stitching stand up to rough conditions. I find that steel-toe boots last longer than soft toe options, especially in demanding jobs.

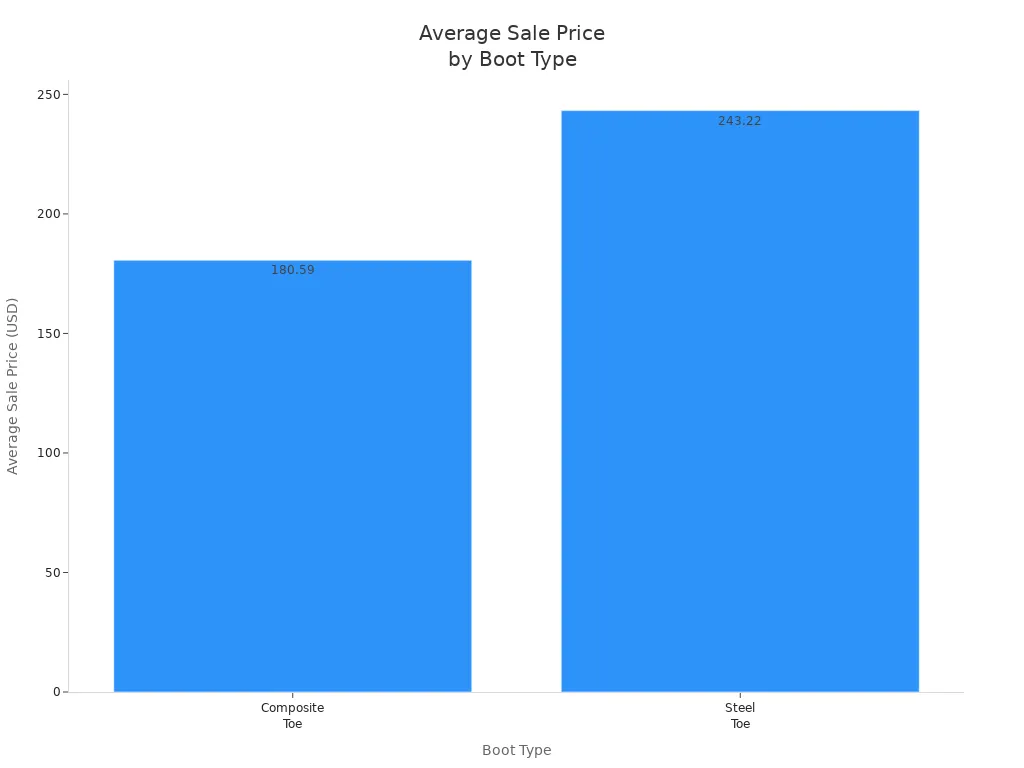

Steel-toe boots also offer affordability compared to composite toe boots. I often see prices for steel-toe boots ranging from $156.99 to $294.95, while composite toe boots can cost up to $214.99 or more.

| Boot Type | Sale Price | Regular Price |

|---|---|---|

| Composite Toe | $180.59 | $214.99 |

| Steel Toe | $156.99 | N/A |

| Steel Toe | $251.99 | $314.00 |

| Steel Toe | $294.95 | $310.00 |

| Steel Toe | $269.95 | $286.00 |

Cons

Heavier Weight

Steel-toe boots use alloy materials that add weight. I notice that wearing heavy working boots for long shifts increases fatigue. The extra weight strains my muscles and joints, especially when I walk or stand all day. Lighter safety footwear, like composite toe boots, helps reduce foot fatigue and keeps me productive.

- The weight of safety footwear affects my efficiency and comfort during long hours.

- Lighter shoes allow me to work longer without feeling tired.

I have spoken with workers who switched from steel-toe boots to composite options. They report better comfort and endurance, preferring lighter boots for extended shifts.

Cold Transfer

Steel-toe boots conduct cold through the alloy toe caps. In winter, I feel the chill more quickly in steel-toe boots than in soft toe or composite styles. The metal transfers cold from the ground to my feet, which can be uncomfortable during outdoor work. I sometimes wear thicker socks to help, but the cold transfer remains a drawback.

Tip: I always consider the climate and my work environment before choosing steel-toe boots. In cold weather, I look for insulated models or switch to composite toe boots for better comfort.

Steel-toe boots provide unmatched protection and durability, making them the top choice for high-risk jobs and heavy industry. I weigh the pros and cons carefully, balancing safety benefits against comfort and cost. When I need the strongest toe protection, I trust steel-toe boots to keep me safe.

Soft Toe Boots

When to Choose

Light Work

I reach for soft toe boots when my job involves minimal safety hazards. These working boots suit environments where heavy objects or sharp materials rarely threaten my feet. I often see soft toe boots recommended for jobs that require frequent movement or kneeling. Many workers in electrical roles prefer soft toe boots because they do not contain metal components, which reduces the risk of electrical conduction. Extreme temperatures also make soft toe boots a practical choice since they do not transfer heat or cold as quickly as steel-toe boots.

- Jobs requiring minimal foot protection

- Roles involving frequent kneeling or movement

- Electrical work

- Environments with extreme temperatures

Soft toe boots work well for professionals who need flexibility and freedom of movement. I notice that retail staff, delivery drivers, and maintenance technicians often choose soft toe work shoes for their daily tasks.

Long Hours Standing

I spend long hours on my feet in some roles. Soft toe boots help me stay comfortable throughout my shift. The lightweight design reduces fatigue, making it easier to walk, stand, and move without strain. Many workers in logistics, healthcare, and hospitality rely on soft toe boots for this reason. I find that soft toe boots offer more comfort than safety-toe boots, especially when I need to stand or walk for extended periods.

Soft-toe boots are generally considered more comfortable than steel-toe boots, particularly for those who are on their feet for extended periods. They are lighter and more flexible, which helps reduce foot fatigue during long shifts, while steel-toe boots, although protective, can be heavier and less flexible, leading to discomfort.

Pros

Comfort

I value comfort above all when my job does not require maximum protection. Soft toe boots provide a cushioned feel and allow my feet to move naturally. The flexible materials adapt to my stride, which helps prevent blisters and soreness. I notice that soft toe boots keep my feet cooler and drier, especially in warm environments. The absence of a steel cap means I do not feel pressure on my toes, even after a full day of work.

Lightweight

The lightweight design of soft toe boots makes a noticeable difference. I compared the average weight of soft toe boots to steel-toe boots and found a significant gap.

| Boot Type | Average Weight (lbs) | Weight Range (lbs) |

|---|---|---|

| Steel toe | 4.1 | 3.7 – 4.5 |

| Soft toe | 2.6 | 2.6 – 3.5 |

- The average weight of steel toe boots is between 3 and 4.5 pounds.

- Soft toe boots weigh around 2.6 pounds.

- The average weight difference is approximately 1.4 to 1.9 pounds.

I feel less tired at the end of my shift when I wear soft toe boots. The reduced weight helps me move quickly and comfortably, which is essential for jobs that require constant walking or standing.

Cons

Less Protection

I must consider the cons before choosing soft toe boots. The most significant drawback is the reduced protection. Soft toe boots do not shield my feet from heavy impacts or compression. I avoid wearing them in environments where falling objects or sharp debris pose a risk. Some employers require safety-toe boots for compliance with safety standards, so I always check my workplace guidelines.

Note: Soft toe boots are not suitable for high-risk jobs. I recommend steel-toe boots or other safety footwear when maximum protection is necessary.

I also notice other cons, such as limited durability in harsh conditions. Soft toe boots may wear out faster if exposed to rough surfaces or chemicals. The lack of a reinforced toe means my boots can lose shape over time. I weigh these cons against the benefits of comfort and lightweight design before making my decision.

Soft toe boots offer flexibility and comfort for workers in low-risk environments. I choose them for jobs that demand long hours of standing or walking. I always balance the pros and cons to match my footwear to my work needs.

Key Factors

Work Environment

When I select working boots, I always start by evaluating my job site. The environment shapes my choice more than any other factor. I look for hazards that could threaten my feet. I check if I work around heavy machinery, sharp debris, or slippery floors. I also consider the temperature. Cold weather makes steel toe boots less appealing because they transfer cold quickly. Wet conditions push me to choose boots with waterproofing. Slippery surfaces require slip-resistant soles. I never ignore these details because they directly affect my safety and productivity.

- I assess hazards associated with my tasks before choosing a boot type.

- I pay attention to temperature conditions since they impact comfort and safety.

- I look for waterproofing features when I work in wet environments.

- I choose boots with slip-resistant designs for slippery surfaces.

I always match my footwear to the demands of my workplace. This approach keeps me safe and comfortable throughout my shift.

Safety Standards

I never compromise on safety standards. I check if my employer follows OSHA regulations and industry guidelines. These standards protect workers by requiring proper footwear in hazardous environments. I always look for boots that meet ASTM and OSHA requirements. This ensures my boots provide the right level of protection.

| Standard | Description |

|---|---|

| OSHA 29 CFR 1910.136 | Legal requirements for foot protection in the workplace. Employers must assess hazards and provide protective footwear if necessary. |

| ASTM F2412 | Test method standard for impact, compression, and puncture resistance testing of footwear. |

| ASTM F2413 | Performance standard defining minimum requirements for safety footwear compliance. |

I read the labels and product descriptions carefully. I make sure my boots meet these standards before I buy them. This step helps me avoid injuries and ensures I comply with workplace policies.

Comfort & Fit

Comfort matters to me every day. I know that poorly fitting boots can cause blisters, fatigue, and even injuries. I always try on several pairs to find the best fit for my feet. I check the length to make sure my toes have room to wiggle. I look at the width to match the natural shape of my feet. I pay attention to arch support because it reduces fatigue and keeps me stable. The toe box should allow my toes to move freely, especially in hazardous environments. I make sure the heel fits snugly to prevent slippage and blisters.

- Length gives my toes enough room without sacrificing a secure fit.

- Width accommodates my foot shape and prevents discomfort.

- Arch support aligns with my foot and reduces fatigue.

- Toe box lets my toes move freely and prevents injuries.

- Heel fit should be snug to avoid slippage and blisters.

I always prioritize comfort when I choose working boots. This decision helps me stay productive and healthy during long shifts. I encourage other workers to do the same and never settle for boots that do not fit well.

Durability

When I invest in working boots, I always pay close attention to durability. I want boots that can handle daily wear and tear without breaking down quickly. In my experience, durability depends on several factors, including the materials, construction methods, and how I care for my boots.

I look for boots made from full-grain leather or high-quality synthetic materials. Full-grain leather resists abrasions and holds up well in tough environments. Synthetic materials can also offer strong durability, especially when reinforced with extra stitching or overlays. I avoid boots with thin or low-grade uppers because they tend to wear out faster.

The construction method matters a lot. I prefer boots with Goodyear welt or direct-attach construction. Goodyear welted boots have a stitched edge that connects the upper, insole, and outsole. This method creates a strong bond and allows for resoling, which extends the life of the boots. Direct-attach construction fuses the sole to the upper, making the boots more flexible and resistant to water. I stay away from glued soles because they often separate after heavy use.

I also check the outsoles. I want slip-resistant, oil-resistant, and abrasion-resistant soles. These features help the boots last longer, especially if I work on rough or slippery surfaces. I inspect the stitching and seams for reinforcement. Double or triple stitching adds strength and prevents the boots from falling apart.

Tip: I always clean my boots regularly and apply conditioner to leather uppers. Proper care keeps the materials strong and prevents cracking.

Steel toe boots usually last longer than soft toe boots in harsh environments. The steel cap protects the toe area from crushing and wear. Soft toe boots may wear out faster if exposed to heavy impacts or rough surfaces. However, if I work in a clean, indoor setting, soft toe boots can last just as long with proper care.

Here a quick checklist I use to judge durability:

- Full-grain leather or reinforced synthetic uppers

- Goodyear welt or direct-attach construction

- Slip-resistant, oil-resistant outsoles

- Reinforced stitching and seams

- Regular cleaning and conditioning

Durability saves me money in the long run. I would rather pay more upfront for boots that last than replace cheap boots every few months. I always match the durability of my boots to the demands of my job.

Alternatives

Composite Toe Boots

When I need protection but want to avoid the weight and cold transfer of steel toe boots, I often choose composite toe boots. These boots use non-metal materials such as heavy-duty plastics, carbon fiber, or rubber. I find them lighter than steel toe boots, which helps me stay comfortable during long shifts. Composite toe boots do not conduct electricity, so I feel safer when I work around electrical hazards. They also provide solid protection against impact, crushing, and puncture, making them suitable for moderate-risk environments.

I rely on composite-toe work boots when my job requires all-day mobility. Their lightweight design reduces fatigue, especially when I walk or stand for hours. I also appreciate their superior temperature insulation, which keeps my feet comfortable in extreme weather conditions. If I need to pass through metal detectors frequently, composite toe boots never trigger alarms, saving me time and hassle.

Here are the main features that set composite toe boots apart:

- Made from non-metal materials like carbon fiber, plastic, or rubber.

- Lighter than steel toe boots, ideal for prolonged wear.

- Do not conduct electricity, safer for electrical work.

- Meet or exceed industry safety standards for impact and compression resistance.

- Provide better insulation against heat and cold.

I compare composite toe boots to steel toe and soft toe boots using the table below:

| Boot Type | Protection Level | Comfort Level | Cost Level |

|---|---|---|---|

| Steel Toe Boots | Maximum | Heavier, less comfort | Often budget-friendly |

| Soft Toe Boots | Lower | More comfortable | Generally affordable |

| Composite Toe Boots | Good | Lighter, more comfort | Can be more expensive |

Composite toe boots cost more than steel toe or soft toe boots, but I believe the comfort and safety benefits justify the investment for many workers.

Other Options

Sometimes, I need alternatives to steel toe, soft toe, or composite toe boots. I look for footwear that matches my specific job requirements. Aluminum toe boots offer lightweight strength and are popular in the aircraft industry. Carbon toe boots have become the most popular type, providing excellent protection with minimal weight. Alloy toes use materials like aluminum, making them lighter than steel. Nano toes use advanced carbon fiber, which makes them thinner and lighter than traditional composite toes.

I also consider met-guard styles when I need extra protection for my forefoot. For temporary or permanent use, OSHATOES fit over my existing footwear. They are lightweight and comfortable, making them a practical solution for visitors or short-term tasks.

Here is a quick overview of other protective footwear options:

| Type of Footwear | Description |

|---|---|

| Aluminum Toes | Lightweight and strong, popular in aircraft industry |

| Composite Toes | Previously common, now largely replaced by carbon toes |

| Carbon Toes | Most popular type, found in many new boots and shoes |

I always match my footwear to the demands of my job, considering protection, comfort, and cost. The right choice keeps me safe and productive, no matter where I work.

Decision Tips

Match to Job

I always start by matching my working boots to the specific hazards I face on the job. Every workplace has unique risks, so I pay close attention to the environment and tasks. I use a checklist to make sure I select the right features: